Learn About Our Technology

How does it work?

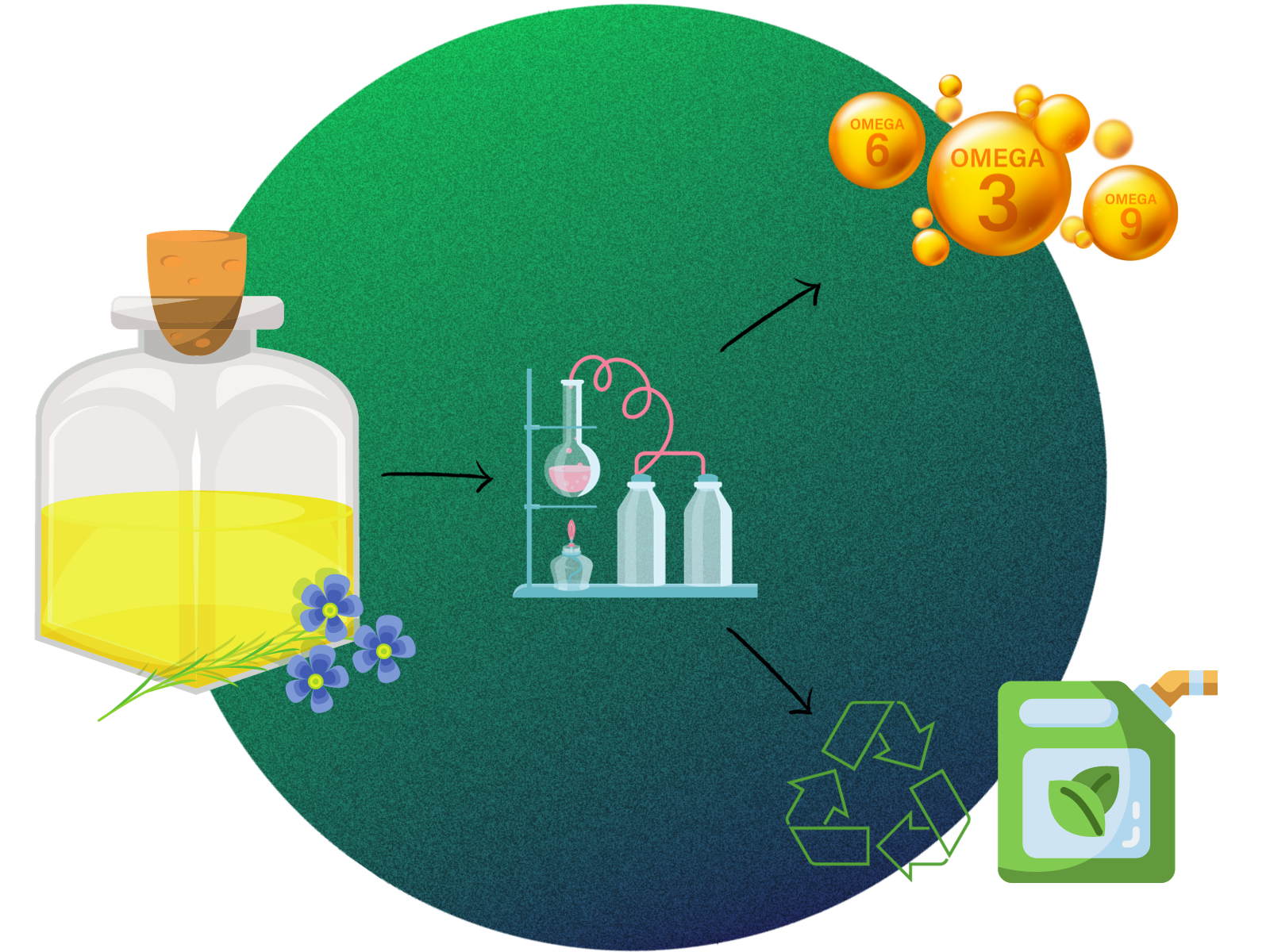

The following is an abbreviated description of the creation of our product.

Everything starts with flax

The process begins with the careful selection of high-quality flaxseeds. The seeds should be clean, free from contaminants, and of the best quality to ensure the resulting oil meets high standards. The cleaned flaxseeds are then subjected to a cold-pressing process. In this method, mechanical pressure is applied to the seeds without the use of heat or chemicals. Cold-pressing helps maintain the oil's natural flavor and nutritional qualities. The flaxseeds are crushed to release their oil content. This is achieved using hydraulic presses or screw presses, depending on the scale of production. The pressure applied separates the oil from the seed's solids.

The esterification process

Before esterification can occur, the flaxseed oil undergoes a purification process. This step removes impurities, contaminants, and any unwanted compounds to ensure that the starting material is of high quality and purity. The core of the esterification process is the chemical reaction that converts ALA molecules into omega-3 fatty acid ethyl esters. This reaction involves the use of ethanol (ethyl alcohol) and an acid catalyst. Ethanol replaces the glycerol backbone of ALA to form ethyl esters. After the esterification reaction, the mixture contains both omega-3 ethyl esters and ethanol. To separate these components, the mixture is subjected to distillation or other separation methods. This step isolates the omega-3 ethyl esters from the ethanol.